1. Matla a enjene a lekane 'me ts'ebetso e tloaelehile, empa lebelo la mochine le lieha' me ho cheka ho fokola

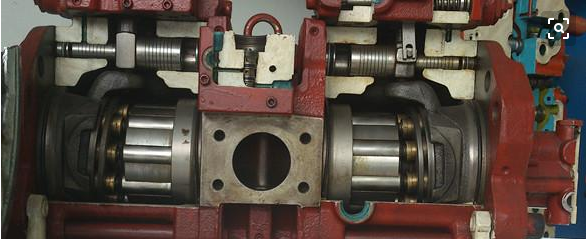

Pompo ea hydraulic ea excavator ke pompo e feto-fetohang ea plunger. Ka mor'a ho sebetsa ka nako e itseng, likarolo tse ka hare tsa hydraulic tsa pompo (silinda, plunger, poleiti ea kabo, poleiti ea likoti tse robong, turtle back, joalo-joalo) e tla apara ka mokhoa o feteletseng, e leng se bakang palo e kholo ea ho lutla ka hare. Lintlha tsa parameter ha li hokahane, e leng se etsang hore ho be le phallo e sa lekaneng, mocheso o phahameng haholo oa oli, lebelo le liehang, le ho se khone ho theha khatello e phahameng, kahoo ho tsamaea ho lieha 'me ho cheka ha ho sebetse. Bakeng sa mathata a joalo, pompo ea hydraulic e tlameha ho tlosoa ebe e romelloa k'hamphaning ea litsebi bakeng sa ho lokisa liphoso. Pompo ea hydraulic e tlameha ho buloa bakeng sa tekanyo ea data ho netefatsa bothata ka moepolli. Likarolo tse ke keng tsa sebelisoa li lokela ho nkeloa sebaka, likarolo tse ka sebelisoang li lokela ho lokisoa, 'me pompo ea haeteroliki e tlameha ho kopanngoa hape. Qetellong, e-ea bencheng ea ho lekanya thepa bakeng sa ho lokisa liphoso. Bapisa feela likarolo tse bonolo tsa sistimi ka 'ngoe (khatello, phallo, torque, matla, joalo-joalo).

2. Ho tsamaea tseleng, 'me ho tsamaea ha letsoho le le leng ha hoa lokela

Lipompo tsa Hydraulic li arotsoe ka lipompo tse ka pele le tse ka morao kapa lipompo tse letšehali le tse nepahetseng. Haeba ho kheloha ho tsamaea ho bontša hore e 'ngoe ea lipompo e fosahetse, tsela e bonolo ka ho fetisisa ea ho ahlola ke: fetola liphaephe tse peli tsa oli tse nang le khatello e phahameng ea pompo ea hydraulic. Haeba leoto la pele le liehang le fetoha kapele, leoto le potlakileng le fetoha kapele. Haeba e lieha, e paka hore e 'ngoe ea lipompo e fosahetse. Bakeng sa bothata ba mofuta ona, o hloka ho tlosa pompo ea hydraulic, ho nkela lisebelisoa sebakeng sa pompo e le 'ngoe, ebe u ea bencheng ea calibration e tsoang kantle ho naha bakeng sa debugging. E boetse e rarolla bothata ba ho sisinyeha ho sa khotsofatseng ha molamu o le mong.

3. Matla a enjene a lekane, empa koloi e tenehile (e bipetsane)

Pompo ea hydraulic ka boeona e boetse e na le matla a itseng. Haeba matla a hydraulic a le kholo ho feta matla a enjene, koloi e tla khomarela (e khomaretsoe). Sena se hloka ho lokisa pompo ea hydraulic bencheng ea calibration e tsoang kantle ho naha le ho fokotsa matla a pompo ea haeteroliki ho 95% ea matla a enjene.

4. Ha mochine o bata, ntho e 'ngoe le e' ngoe e tloaelehile. Ha mochine o chesa, ho sisinyeha hoa lieha 'me ho cheka ho fokola

Mofuta ona oa bothata o bolela hore pompo ea hydraulic e fihlile moo e tlamehang ho fetoloa. Likarolo tse ka hare tsa pompo ea hydraulic li apere haholo. Tšebeliso e tsoelang pele e ka baka ho senyeha ho hoholo ha likarolo tse ka hare tsa pompo ea hydraulic. Likarolo tsohle tse ka hare tse senyehileng li tlameha ho nkeloa sebaka, ho kopanngoa hape le ho lokisoa bencheng ea litekanyo tse tsoang kantle ho naha ho khutlisetsa pompo ea haeteroliki maemong a eona a tloaelehileng.

Haeba excavator ea hau e hlokalisebelisoa tsa excavatorjoalo ka lipompo tsa haeteroliki, kapa haeba u batla ho rekabaepi ba dikepele li-excavator tsa khale, u ka ikopanya le rona le ho re botsa. ccmie o tla o sebeletsa ka pelo yohle.

Nako ea poso: Apr-30-2024